Get Fracking

+ BY THOMAS K. GROSE

+ PHOTOGRAPH BY MARK OVASKA/REDUX

Engineers stoke the natural-gas boom – and investigate its risks.

Beneath the headline “Good News About Gas,” Massachusetts Institute of Technology chemistry professor John Deutch, a former U.S. undersecretary of energy, deputy defense secretary, and CIA director, rhapsodized about technological advances that make it economical to extract vast amounts of natural gas from shale fields deep below the Earth’s crust. “It is perhaps a permissible exaggeration to claim a natural gas revolution,” he wrote in the January Foreign Affairs. A few months later, the Paris-based International Energy Agency proclaimed that recoverable shale gas reserves worldwide were ushering in a “golden era” for natural gas.

Revolution? Golden era? Those aren’t terms scientists toss about lightly. Why the euphoria? Natural gas offers many benefits to a world desperately trying to reduce its carbon footprint. It pollutes, but it still burns much more cleanly than oil and coal. A June MIT study, in which Deutch participated, estimated that replacing U.S. coal-fired electric plants with gas, while simultaneously reducing energy demands, could cut carbon dioxide emissions by up to 50 percent by 2050. And if it were put to greater use as a transportation fuel, it could help reduce America’s dependence on imported oil. Moreover, the United States now has access to far more gas than previously expected. Last spring, the federal Energy Information Administration estimated that America’s recoverable shale gas reserves total 827 trillion cubic feet – more than double its 2010 estimate.

The prospect of abundant global supplies of natural gas is one reason for a swelling demand for petroleum engineers, a consequent surge in student enrollment, and stiffer competition at schools like the University of Houston, which is expanding its petroleum engineering program. Far and away, petroleum engineering is the highest paying engineering degree, starting around $100,000 a year. Fortune reports that nearly all petroleum engineering grads from schools like Texas A&M and the Colorado School of Mines last year found employment. In Washington, talk of a shale gas bonanza has strengthened opponents of President Obama’s push to advance renewable fuels and a clean-energy economy.

Critics say the optimism over shale is misplaced. They fear the processes used to extract shale gas will contaminate groundwater supplies and fill the air with smog-causing pollutants. The surge in shale gas production has generated a spate of lawsuits, bans, and congressional and statehouse hearings. Last month, an Energy Department-appointed task force – led by Deutch – said the processes posed a potentially serious problem and urged both government and industry to take preventive action: “Effective action requires both strong regulation and a shale gas industry in which all participating companies are committed to continuous improvement.”

MIT’s study concludes that environmental problems caused by shale gas production are “challenging but manageable.” That translates into the need for better regulation, more government-funded basic research, and applied research and development by industry. And just as engineers are key to extracting gas from shale, they’re also examining potential dangers to the public.

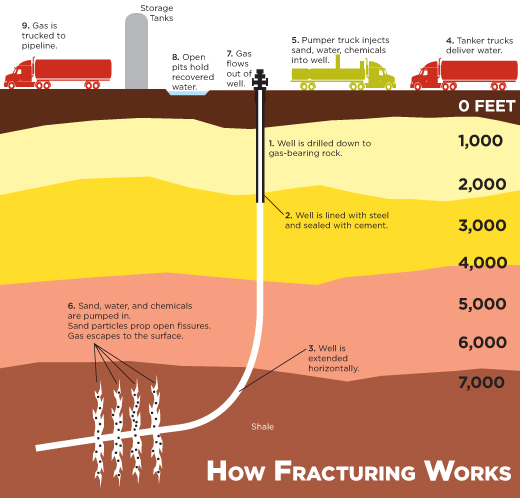

The technology behind the shale boom involves horizontal drilling and hydraulic fracturing – or fracking, to use the industry nickname. It releases gas from organic-rich shale, a splintery sediment formed of compacted mud, clay, and minerals, by blasting the rock with millions of gallons of water mixed with sand and chemicals — some toxic — to create fissures. Fracking is not new; the industry has used it in oil wells for around 60 years. In the 1980s it began to be used to improve production of “tight gas” from low-permeability wells.

While geologists have long known that gas was locked within the pore spaces and vertical fractures of 400 million-year-old shale deposits, until just a few years ago there was no economical way to tap into it and make it flow out quickly. Then, during a period when domestic gas prices began rising – they peaked in 2008 at $13 per million Btu – entrepreneurial operators in Texas’s Barnett shale field began experimenting. They combined horizontal drilling – drilling a mile down, then a mile or more sideways into the shale – with fracturing. It worked like a charm, though initially the process was quite expensive. But technological advances were so swift that the process remained cost effective even as gas prices tumbled.

Now the price is creeping back up. Michael Economides, a chemical engineering professor at the University of Houston, forecasts that the domestic price of gas – now about $4 – will rise to $6 later this year, and to $8 by 2015. Yet even at those prices, gas will still remain much cheaper than liquid petroleum, says research engineer Francis O’Sullivan, executive director of MIT’s Energy Sustainability Challenge Program. Gas at $6, on an energy-equivalent basis, is as cheap as $36-a-barrel oil.

Groundwater Pollution

So shale gas is plentiful and a bargain. But concern about safety is mounting. In May, Duke University scientists reported finding evidence of methane contamination of drinking water associated with shale gas extraction. They investigated 60 water wells in Pennsylvania, one of several states that are home to the massive Marcellus field, and found high levels of methane in 13 of 26 wells located within a kilometer of a fracking site. Writing in the Proceedings of the National Academy of Sciences, the Duke team suggested there are “important environmental risks accompanying shale gas exploration worldwide.” MIT’s group looked at 43 major reported incidents of environmental damage. Of these, almost half appeared to involve natural gas contamination of shallow ground water zones.

Fracking itself evidently was not the culprit, though that may be little comfort to people living atop polluted wells. “My best guess is it leaks out of the well casings,” says Robert Jackson, a biologist and chemical engineer who wrote the Duke paper. MIT’s O’Sullivan agrees. “It’s always a poor cement job.” Duke’s investigators looked for, but did not find, evidence of fracking fluids in water supplies. However, Jackson says, it is possible that pressure created by fracking inadvertently cracks the casings. “No one knows if hydraulic fracturing causes the leaks or not,” he says.

Most of the fracking fluid injected into gas wells remains below ground, often separated from aquifers by thousands of feet “of thick, nonporous rock that won’t let the fracturing fluids through,” explains Jennifer Miskimins, an associate professor of petroleum engineering at the Colorado School of Mines.

Still, the entire extraction process poses other risks, including the immense amount of water required, contamination from wastewater disposal, and spills of drilling fluids, or “slickwater,” which typically contain hydrochloric acid and chemicals used in bleaches, medical disinfectant, and glass cleaner. Some slickwater — perhaps around 25 to 30 percent — does return to the surface as flowback. And a third of the 43 incidents MIT examined resulted from spills or improper disposal of flowback.

One possible fix: recycling of flowback. That’s a process the industry began testing in 2004, and it’s now becoming standard procedure, in part because there’s evidence that recycled frack fluids are highly effective. Also, the less water used, the less there is to dispose of, which saves money. “There is a huge (research) opportunity to reduce the volume of water and the number of chemicals used” in fracking, O’Sullivan says. Kelvin Gregory, a civil and environmental engineer at Carnegie Mellon University, is leading a $1 million, three-year study on ways to improve the recycling of fracking fluids. He notes, “Companies realize you don’t always have to frack with a witch’s brew of chemicals.”

Exhaust Fumes

Air pollution has also drawn attention from federal and state officials. Many operators use diesel-powered compressors to pump the water and run heavy equipment, and truck traffic in and out of drill sites is nonstop. A study at the Barnett field found that oil and gas production there in 2009 churned 18,615 tons of nitrogen oxides into the air, equivalent to what an unfiltered, midsized coal-fired plant would produce. Earlier this year, a Cornell University study claimed that shale gas production may be twice as dirty as coal. But the IEA’s spring report found that shale gas’s CO2 emissions, from well to burn, were only 3.5 percent higher than conventional gas.

One way to cut emissions is to use natural gas-powered compressors. Efforts to reduce water usage – thus haulage – should cut down on truck traffic, thereby also reducing diesel fumes.

How long can the shale boom last? Reports in the New York Times have questioned the IEA’s rosy estimate of shale reserves, and noted that while some shale wells were big moneymakers, many others were losers. The industry’s track record, however, is one of drilling many wells and achieving profits based on a performance-probability distribution. Companies also take account of the speedy decline of many wells by planning to make their profits on each well in the first year or two. Miskimins says the industry has shown it can increase productivity while shrinking costs. Major energy companies, like Exxon Mobil, are now getting involved in shale gas extraction. Experts say they’re less likely than small, independent operators to take shortcuts that lead to leaks and spills.

Still, Economides worries that opponents’ “hysteria” will spur lawmakers to over-regulate and cause operators to walk away from shale. Carnegie Mellon’s Gregory says both sides have been guilty of hyperbole. “I hope we can cut through all that with some strong science.” With a mix of annoyance and amusement, he offers an anecdote that says a lot about engineers’ stake in a shale boom – and in a strong domestic petroleum industry. A student of his who graduated just two years ago now works for Schlumberger, a leading industry service company: “He’s earning twice as much as me.”

Thomas K. Grose is Prism’s chief correspondent, based in London.

Category: Features