Deadly Ingredients

BY CHARLES Q. CHOI

Nanosatellites bring space discovery to campus at down-to-earth prices.

What’s smaller than a breadbox, nearly as affordable, and is opening up space exploration? Though it may sound like the answer to an old quiz-show query, MIT’s loaf-size ExoplanetSat and some 20 other tiny “nanosatellites” that NASA plans to launch in the coming year represent a bold break from the past. They also highlight the powerful new role of engineering departments in tackling one of astronomy’s biggest tasks: discovering distant planets that could support life.

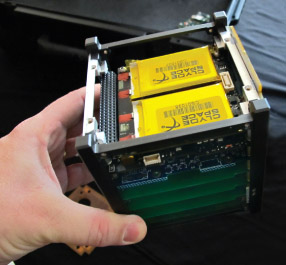

Unlike well-funded federal or industry-led revolutions in space technology, nanosatellites are the university equivalent of garage start-ups. One popular type, the CubeSat, occupies a frame just 10 centimeters across and was “based off the size of a Beanie Baby box I found in a shop,” says coinventor Robert Twiggs, a professor of earth and space science at Morehead State University. Cheap and lightweight — just 2 to 22 pounds — these miniature satellites have thrust thousands of undergraduates into design/build experiences that not only fit departmental budgets and course requirements but also let students address some of the same cutting-edge space challenges that engage the military, space scientists, and industry.

Engineering educators find that nanosatellites motivate undergraduates to master difficult material. “Working on a satellite that will go up to space on a rocket appeals to a lot of students, and can attract them into putting in long hours and dealing with a lot of frustration to learn something they didn’t know before,” says Bruce Yost, a project manager at NASA’s Ames Research Center who has worked with students on a nanosatellite designed to look for organic compounds in the cosmos.

A lucky “perfect storm”

The embrace of nanosatellites was spurred by advances in microelectronics that enabled even minuscule packages to pack a huge performance punch. “We had miniaturization of sensors, electronics, communications packages, cellphones, laptops, and all that — a perfect storm going our way,” explains Twiggs’s CubeSat coinventor Jordi Puig-Suari, a professor of aerospace engineering at California Polytechnic State University. The small satellites’ arrival coincided with the government’s need to train aerospace engineers who held U.S. citizenship and could be cleared for sensitive projects. Out of this need for talent sprang the University Nanosat Program (UNP), now run by the Air Force in partnership with the American Institute of Aeronautics and Astronautics. Since its inception in January 1999, some 4,000 undergraduates, mostly in engineering, from at least 27 universities have participated. Participants go through a two-stage process: In the first phase, students design and build a prototype nanosat to enter in a flight competition. The second phase involves integrating and testing systems in preparation for a potential launch opportunity.

UNP Program Manager David Voss of the Air Force Research Laboratory got involved as a Boston University doctoral student in electrical engineering. He oversaw 60 undergraduate and graduate students working to design and engineer a five-system UNP nanosatellite to hover over the aurora borealis and test existing computer models to better predict space weather that can disrupt cellphone communications.

As space systems go, they’re relatively quick to build, “so students can see a project they worked on from the start launch while they are still in school, something they find very exciting,” says Mason Peck, associate professor of mechanical and aerospace engineering at Cornell University. Still, small doesn’t mean simple. Like their larger cousins, nanosatellites have solar panels, batteries, power systems, antennas, command and telemetry systems, and a host of mechanical structures. Students not only must create exceptionally robust systems that can survive the launch as well as the cold, heat, and radiation found in the vast vacuum of outer space; they also need to identify and fix fatal design flaws before their satellite fails beyond reach of repair. “You have to put a lot of effort up front and be really confident when it launches,” says Peck.

Beyond developing technical knowledge, students hone such practical skills as working on diverse teams. Consider MIT’s ExoplanetSat, scheduled to launch in 2012. The $5 million nanosatellite, designed to scan space for potentially life-sustaining, Earth-like planets, uses high-performance optics that can measure the dimming of a star as an orbiting planet passes in front – data that can help tell how large such a world is and its distance from its star. The project demanded a variety of expertise. “Engineering students might design solar panels and rely on orbits that collect power most effectively, but science students explain that idea can’t work, since it means they can’t observe the stars properly,” explains ExoplanetSat project leader Sara Seager, a professor of planetary science and physics. “So there’s a constant back and forth.” That discourse also affects how students perceive their roles on projects. “Students learn how to integrate something complex; the environment is really multidisciplinary,” notes Cornell’s Peck. “You can’t just be an expert in one little discipline — you have to take into account how your work might affect others and how theirs might affect yours.” Adds NASA’s Bruce Yost: “If some problem pops up, it’s not just the electrical guy’s problem. It’s everyone’s problem.”

Valuable Skills

Such experience attracts employers. “They’ve definitely got jobs lined up,” says Peck, whose students are “heavily recruited” by Boeing, Lockheed, NASA, and the Air Force. Nor is aerospace the only interested sector. CubeSat coinventor Puig-Suari has seen Cal Poly students hired by Apple. “The kinds of skills students are learning working on complex systems have a value beyond the space industry,” he says.

Ironically, that value went largely unnoticed at first by many. “Naysayers said nanosatellites were too small to do anything useful,” since telescopes needed large apertures that collect light to see well, recounts NASA’s Yost. At best, government and industry experts thought nanosatellites “were toys, like owning a model car,” Peck notes. At worst, they were potential space debris that could harm satellites, astronauts, and spacecraft.

Concern and scorn dissipated with each nanosat launch, however. “The whole attitude regarding nanosatellites began to change” as their usefulness and “significantly lower prices” became clear, says CubeSat coinventor Twiggs. Today, NASA, the military, and aerospace companies have robust programs. Engineers, for example, use nanosatellites to troubleshoot components designed for larger satellites. The military is investigating them as a potentially quick, inexpensive way to set up battlefield telecommunication networks. Scientists want them for observing Earth, deep space, and the behavior of microbes in orbit, while industry hopes they will help boost understanding of risky space environments and hazards spacecraft might face. “Government and industry have finally caught on,” marvels Wayne Shiroma, an assistant professor of electrical engineering at the University of Hawaii, Manoa. His electrical and mechanical engineering students won two awards at the UNP competition in Albuquerque, N.M., last January.

Nanosatellite proponents see this transformation as an example of how engineering undergraduates can help develop the underpinnings of viable future capabilities and enterprises. As UNP program manager David Voss notes, “students don’t know what you are and aren’t allowed to do, and so can lead to innovations.” Meanwhile, increasingly sophisticated technology is finding its way into nanosatellites as universities partner with industry. With ExoplanetSat, for instance, MIT partnered with Draper Laboratory to develop battery-powered piezoelectric drives that control the motion of the imaging detector an order of magnitude more precisely than any previous nanosatellite.

Emerging companies are now supplying, off the shelf, components that were once highly specialized, freeing faculty and students to concentrate on post-launch operations. As they analyze data from satellites already aloft, researchers also are investigating ways to overcome limitations imposed by small size, such as having an array of nanosatellites work together like one big space telescope. The challenges, however, are significant. “You have to have incredibly accurate timing and know the exact position of each element of such an array,” says NASA’s Yost, adding that high-accuracy atomic clocks, GPS, and range-finding technology would all have to come way down in size to fit inside each nanosatellite. Given the speed with which miniaturization advances, however, that could well become possible. Another development seen to hold promise: fusing nanosatellites together to create larger, more capable satellites.

Not everyone is thinking big, however. Twiggs and his Morehead State students are pursuing what they call a PocketQub, a satellite just 2 inches or so wide. “You can put eight of these in a regular CubeSat, so theoretically they’d cost an eighth,” he calculates. Cornell’s Peck and his collaborators are going even smaller with the idea of a satellite on a chip, called a “Sprite,” with numerous inch-square orbiters dispersed per launch. They already are testing these cracker-size devices with solar and radio cells on the international space station. Cornell student Zac Manchester has even designed a container to deliver a payload of solar-powered “ChipSats.” Called KickSat, it will allow anyone to launch his own micro-Sputnik for $300 apiece. So far, 30 sponsors have signed up — and Manchester hopes to lift off in 2013. Concludes Stephen Arnold of the Naval Research Lab, “Sometimes smaller is better.”

Charles Q. Choi is a New York-based freelance writer specializing in science.

Category: Features