“Patch and Pray”

To most Minneapolis commuters, Wednesday, August 1, was just another day of traffic tedium. The evening rush hour traffic was crawling at its usual glacial pace, the kind of stop-and-go grind that urban commuters around the world face twice daily with weary resignation. Those whose journey required traversing Minneapolis’ busiest bridge, the eight-lane I-35W across the Mississippi River, were putting up with slower than usual traffic, thanks to repair work that left only one lane open in each direction. Everything seemed mind-numbingly ordinary.

Then came an unworldly deep rumbling sound. The 40-year-old bridge swayed and buckled. And then it collapsed, much of it tumbling into the swirling waters below, taking cars and trucks with it. Within seconds, a frustrating midsummer’s commute turned into a catastrophe of historic proportions, leaving 13 people dead and more than 100 injured.

The collapse of the I-35W bridge occurred just two weeks after another deadly drama, one less epic but significant, nonetheless. On the evening of July 18, a midtown Manhattan steam pipe that had been laid in 1924—when Calvin Coolidge was president and Prohibition reigned—burst open spectacularly, shooting up a 77-story plume of smoke. The explosion killed one person, injured 30 others, nearly buried a tow truck and rattled the nerves of New Yorkers, who feared another terrorist attack.

Minnesota’s bridge disaster and New York’s exploding steam pipe both bring into sharp focus a major public safety and economic dilemma facing America: the decaying condition of much of its aging infrastructure. Political neglect and lack of adequate funding have combined to jeopardize the massive transportation and utilities framework upon which this country’s economic well-being rests.

Not only does the current perilous situation place lives at risk—an estimated one third of the 40,000 highway deaths a year are caused by bad roadway conditions—it also threatens America’s competitiveness. Says Patrick J. Natale, executive director of American Society of Civil Engineers (ASCE): “We believe that a strong infrastructure supports a strong economy, and that a weak infrastructure can’t support it.” The Urban Land Institute (ULI) reports that the U.S. transportation system alone faces an emerging crisis. In a recent survey, the institute queried 30 state transportation planning directors, 83 percent of whom say that America’s transportation infrastructure won’t hold up to demand within a decade.

A list of what is usually included within the infrastructure rubric demonstrates the vastness of the problem: airports, roadways, bridges, subways, railways, electric power systems, flood-control levees, dams, tunnels, and pipes for water, sewage, natural gas and steam. No section of the country’s infrastructure is performing well. America’s interstate highway system, all 46,000 miles of it, was largely built in the 1950s and ’60s, and the ASCE says 34 percent of it is in mediocre to poor shape.

The ULI report concurred, stating that the postponement of so much highway maintenance each year has created a problem “so gargantuan nobody knows where to begin.” Of the approximately 600,000 bridges in the U.S., 27 percent are structurally deficient, while deteriorating tracks contribute to ongoing train derailment across the country. There have been 29 recent dam failures over the past two years, and in California alone, 1,600 miles of levees are in worse shape than those that flooded New Orleans during Hurricane Katrina. And let’s not forget the massive power outage in 2003 that darkened much of the Northeast. Two years ago, the ASCE gave America’s infrastructure an overall grade of “D,” and the low marks were spread across the board.

Moreover, much of the problem—particularly that of pipelines—is out of sight, and so, out of mind. It’s buried deep beneath city streets and sidewalks, in what Zimmerman calls the “hostile environment” of a damp subterranean world that is a tangle of pipes and cables. Water lines are riven with leaks, and huge amounts of drinking water just trickle away, says William C. Miller, a Temple University civil engineer. “But they only fix them when [the problem] comes to the surface.”

Too little money, poorly allocated

Underfunding is a main culprit for the state of disrepair. It is not that money is not allocated, it’s that the amounts are usually too small. According to ASCE, an investment of $1.6 trillion is needed to address the problem. In 2005, Congress approved a $283 billion highway bill and proclaimed it the largest in history. But it was still $67 billion shy of what the U.S. Department of Transportation (USDOT) had requested. It’s also not unusual for states to re-direct money allocated for bridge and highway repairs to help balance budgets if they get into a fiscal jam. Because Washington lawmakers are averse to raising the federal gas tax, the purchasing power of the Highway Trust Fund, which pays for much of the nation’s road construction and repairs, has eroded by half over the last 40 years.

At the same time, unless $50 billion is invested in America’s power grid over the next five years, lights are going to go out, ASCE warns. And it’s not just the inadequate sums that worry experts. Money allocated to infrastructure—particularly Congressional earmarks—is usually for construction of new facilities, not repairs. “They’d rather cut ribbons,” says Pablo L. Durango-Cohen, an assistant professor of civil engineering at Northwestern University. He adds that decisions of such importance shouldn’t be based on public opinion, but often they are. And in such a climate, repairs lose out because, as Natale notes, “they are not sexy.”

The monumental size of America’s infrastructure challenges—and the staggering sums required to mend things—also works against financing, Miller says. “It’s mind-numbing. The public just zones out.” To be sure, horrific events like the collapse of I-35W focus public attention for a while, but as the stories slip off the front pages, the urgency of the dilemma ebbs, as well. Says Natale: “Our mentality is patch and pray. Is that wise?”

Definitely not, says Professor Samer Madanat, head of the Institute of Transportation Studies at the University of California, Berkeley. He stresses that a smarter way to tackle the problem and make use of scarce funds can be found by dividing infrastructure management into three categories: inspections, predictions, and decision-making. Inspections, which include increased use of faster, automated, more comprehensive high-tech sensors and detectors, allow engineers to know the current status of any given system. “It’s a lot more cost effective when you know where to dig,” explains Anil Kumar Agrawal, a civil engineer at the City University of New York. “Emergency repairs are always more costly.” Predictions are made from advanced statistical models that calculate the probable state of a system under different, future scenarios. And decision-making “is juggling a lot of interests and resources,” Madanat says, incorporating math-based optimization techniques to give planners the tools to make the tradeoffs necessitated by tight budgets.

New technology

The task of fixing the country’s decrepit infrastructure systems is enormous. But academic engineers at schools around the country are working on technologies to improve all three areas of inspections, predictions, and decision-making. Ranging from high-tech monitors to complex mathematical models to brand-new composite materials, they are coming up with solutions that could not only make the job easier but also improve future construction, maintenance, and repair.

For example, researchers are working on monitoring technologies that will collect more data on a continuing, daily basis, such as microsensors embedded in paints that change colors when trouble is detected, and sensors that that will literally “phone home,” calling engineers’ phones to report dangerous changes. It’s expected that future sensors will also have the ability not only to collect data, but analyze it and offer diagnoses. Research by two Drexel University civil engineers shows that the existing technology of a falling-weight deflectometer could be further developed to help inspectors determine safe load capacities for aging concrete bridges.

Meanwhile, University of Michigan engineers have developed a nanotechnology “skin” that can be sprayed onto structures like a permanent coating of paint. The skin is actually several layers of polymer, each containing a network of nanotubes that measure something different: pH levels and cracking at a minute scale, for instance. The skin’s electrodes are connected to a microprocessor, and once it is activated by an electric charge, it spits out a two-dimensional map that displays underlying corrosion or cracking too small for humans to see.

The use of high-tech monitoring devices, including sensors that utilize ultrasonics, acoustics and strain-monitoring to measure corrosion, temperature changes, fatigue and erosion is a still-developing area. But according to a recent study of monitoring technologies by Iowa State University’s Bridge Engineering Center, most monitors still rely on visual assessments, and need to be fitted where damage is already known or expected to appear, which limits their effectiveness.

If Minneapolis’ I-35W had been wired with a system to monitor its condition, the data might have warned engineers in time to avert the disaster. No one can say so with certainty, because a monitoring system could have been hooked to parts of the bridge that didn’t fail or show signs of potential failure. That said, Durango-Cohen adds, “There are a few documented cases where sensors alerted engineers that failure was about to occur before any signs would have been detected with visual inspections.” Given that this technology is still in its infancy, that’s encouraging.

While many of these technologies are being developed for bridges and other above-ground structures, some could be adapted to pipelines. And work on detection devices expressly for pipes is continuing as well. At Carnegie-Mellon University’s Robotics Institute, researchers have created a 5-foot-long, 4-inch-wide worm-shaped robot intended to check for leaks and pools of seepage water. Fitted with sensors and video cameras, the self-propelled Explorer can scuttle through natural-gas pipelines, even making 90-degree turns, inspecting whichever route it’s sent by wireless remote control. Future versions might make repairs, too. The efficacy and logic of robotic pipe inspections is obvious, but researchers say robots could also be used to inspect parts of bridges that present hazards to humans, such as the undersides of decks. NYU’s Zimmerman cautions, however, that while sensors and robots are wonderful technologies, they too are subject to the same harsh environments that wreak havoc on infrastructure. “They can get mucked up, too,” she cautions.

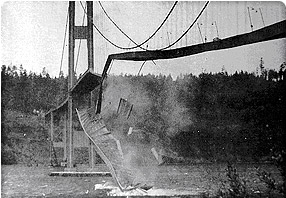

Life’s Lessons In the Classroom When engineering is in the news, it can give teachers useful material. There are lessons to be learned from high-profile failures like the collapse of Minneapolis’ I-35W bridge, as well as from triumphs such as Maine’s cutting-edge new Penobscot Narrows Bridge and Observatory. “It is common for engineering and science faculty to use failures, especially highly-visible ones, to demonstrate engineering and science principles,” explains Jack Lohmann, editor of the Journal of Engineering Education and vice provost for academic affairs at Georgia Tech. And they’re on solid ground when they do. “There is a lot of research on situated learning,” he adds, “It basically shows, and not too surprisingly, students learn better” when learning within a context. Anil Kumar Agrawal, a City University of New York civil engineering professor, agrees: “It is easy to get students excited and involved in such projects, since we all somehow connect to these events.” Moreover, “examples of failures highlight the need to understand engineering fundamentals.” Agrawal plans to use modeling of I-35W in an undergraduate course on finite elements. He also shows how engineers installed dampers to stop the nauseating sway of London’s seven-year-old Millennium Bridge. Engineering breakthroughs are also useful because they focus student attention on the latest research and industry innovations. The Penobscot Narrows span demonstrates the use of a new cable system that allows for stronger stays, easier inspection and replacement, as well as carbon-composite strands that last longer than conventional steel strands. While more recent developments catch students’ attention, some examples are so extraordinary they’ve become classics, like the 1940 collapse of the Tacoma Narrows Bridge in Washington, which was brought down by wind-induced vibrations. Because the entire, stomach-churning collapse was captured on film, it remains one of most infamous bridge failures in the world–and one that can keep even YouTube-generation students riveted. —TG

Prediction: Science and Art

Though planners must know the current state of structures, it’s also helpful for them to know how things may change in the future, depending on conditions. So prediction technology is not just crunching numbers, says Berkeley’s Madanat. “Prediction is a combination of science and art in many ways.” Researchers need to have a full understanding of the materials being scrutinized, such as concrete or asphalt, and how they’re affected by such variables as heat, cold and chloride. “Science by itself is not sufficient,” Madanat adds, “What you can do in a lab is not the same as what you can do in the field, because it’s hard to replicate the environmental factors.”

To address this issue, advanced statistical models combine physical measurements from the lab with observations made in the field. One leading practitioner is Ohio State University’s Rabi Mishalani, an assistant professor of civil and environmental engineering. He’s working on models that can, for example, predict how a road will deteriorate over time, taking in such variables as design and construction standards, as well as location.

Ongoing materials research is also yielding ways to improve and expand the life of structures. For example, researchers are devising improved composite materials. Sheets of fiber-reinforced polymer (FRP) composites can now be epoxied onto bridge piers and pillars, protecting them from erosion and corrosion. The sheets are akin to wallpaper, and are epoxied onto the concrete.

As a result, says Houssam A. Toutanji, an associate professor of civil engineering at the University of Alabama, Huntsville, the strength of existing concrete can be rendered 50 percent stronger than its original composition. That’s because FRPs are more resistant to corrosion, particularly the kind created by road salt or saline water. FRPs are so new that researchers are still testing and modeling to determine how long they’ll last in situ. Yet Toutanji predicts that in some cases, the sheets may endure for 25 years.

The weak link in FRP technology is the glue, so another vital area of research comes in developing epoxies that form stronger bonds. Beneath the concrete, yet another new technology is the use of graphite rebars in place of steel. Not only is graphite more resistant to salt and the elements, it’s 10 times stronger than steel and five times lighter. But it’s also very brittle, so if cracks appear, “it could be catastrophic,” says Huntsville engineering professor John Gilbert. Thus, “monitoring has to be great.”

Nonetheless, engineering researchers continue to devise technologies that will radically change how future infrastructure is built. So-called “smart structures” would be constructed with materials that have sensors embedded in them, using, for example, fiber optics technology. Another exciting possibility is self-healing concrete that can repair itself when cracks occur by activating small capsules containing bonding agents. “That is absolutely the future,” Toutanji says.

The next generation of structures, particularly bridges, may also be built from “cementitious” materials—cement to which other materials have been added, such as lightweight aggregates, silicon or polymers. These materials are being designed to be both strong and impact- and bomb-resistant. “They’re more flexible and not so brittle” as regular concrete, Toutanji says. NYU’s Zimmerman is confident that researchers will also come up with designs to make the inevitable repairs simpler. “We need to build infrastructure in a way that it can be maintained more easily going into the future.” Since so much infrastructure needs to be underground, that means designing pipelines that aren’t so difficult to reach. “We need easier access than jackhammering asphalt,” she says.

The third category of Manadat’s equation of inspections, predictions and decision-making entails determining where and how to spend maintenance funds. And there’s nothing easy about it. Decision-making involves many tradeoffs, since planning managers rarely have the money to do everything that needs to be done. Juggling work on hundreds of thousands of miles of roadways and thousands of bridges is a complex task.

Madanat and Durango-Cohen say managers too often rely on priority lists and do maintenance and repairs on a “worst-first” basis. But that’s wrong way to do it. “It’s reactive and myopic and clearly not efficient”—let alone cost-effective, Durango-Cohen argues. Often, Madanat explains, it’s better to spend small amounts doing maintenance on relatively young facilities. For example, newer pavement will have relatively few cracks, and these are usually small. But as water seeps into those tiny fissures, they enlarge. That’s why the rate of deterioration greatly accelerates as pavement ages. Thus, spending small sums early to fix tiny cracks before they age, grow and become major problems can lengthen the life of pavement and saves big bucks.

Durango-Cohen says civil engineers too often favor infrastructure replacement over routine, preventive maintenance. Instead, the goal should be to increase the lifespan of structures. A good analogy, he says, is the aircraft industry, where rigorous, ongoing maintenance keeps commercial aircraft flying safely for decades.

And that’s where advanced numerical methods of optimization and decision-making software come in. The notion of using computers to help manage assets goes back to the 1950s, and began being used for highway systems in the 1980s. As the first state to apply optimization techniques, Arizona saved hundreds of thousands of dollars a year by spending maintenance money more wisely. Since then, the techniques have not only been used by other states, but applied successfully to the management of sewer lines and tunnels.

Today, researchers are busily working to improve decision-making software—like Durango-Cohen’s adaptation of signal-processing techniques. He stresses that the computerized help is just that: help—a tool that can guide, but shouldn’t be expected to replace, human managers. Nevertheless, one barrier to its more widespread use has been a fear among managers that software programs would make them redundant. He concludes, “It remains to be seen if decision-makers and politicians will be willing to use these tools.”

While engineers can’t do much about chronic underfunding, they are developing technologies that could help cash-strapped agencies get more done for less money. “These things hold a lot of promise,” says Rae Zimmerman, director of the Institute for Civil Infrastructure Systems at New York University.

While too little money may be earmarked for maintenance, there are funds available for infrastructure research projects. “This area is reasonably well-funded,” Madanat says, particularly in the transportation and electrical-systems sectors. The least funded research areas tend to be water and wastewater systems, mainly because the money for those typically comes from municipalities, which are often at the mercy of small, tight budgets. But many breakthroughs developed for highway and bridge maintenance—particularly inspection and prediction methods—are easily adapted to water and sewage systems. “There’s a lot of cross-fertilization,” Madanat says.

Yet Agrawal warns that, even though federal and state transportation departments are willing to fund research, they usually pay for development of near-term technologies, not for science, where possible applications are 10 years down the road.

It seems likely that technologies emerging from academic labs will ease the overwhelming goal of refurbishing America’s sagging infrastructure. But researchers have their work cut out for them. Despite the tremendous advances being made in research, there is still a great deal more to done, even at the most basic level. Three months after Minneapolis’ I-35W bridge groaned, heaved and plunged into the Mississippi’s swift currents, it’s still not clear what caused the structure to fail. As the threat of the aging infrastructure increases with each passing day, researchers must race to find answers. Otherwise, we may be on the road to more ruin and more deadly catastrophes.

Thomas K. Grose is a freelance writer based in London.

Category: Cover Story Features