Beyond the Blueprint

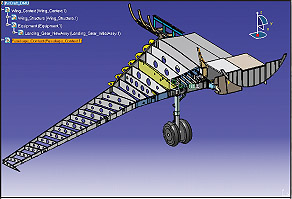

Boeing made aeronautics history in the 1990s when it developed its 777 aircraft using Dassault Systèmes’ three-dimensional computer-aided design software. Yet the plans ultimately ended up on paper. Back then, the blueprint still reigned. Boeing’s new and much anticipated 787 “Dreamliner” commercial jet represents a radically new approach. Using a suite of Dassault software and incorporating product lifecycle management (PLM) concepts, Boeing not only conceived and designed the plane in virtual space but also planned its production and full-life maintenance with 3D software. Nothing was committed to paper. Every one of the millions of parts was virtually simulated and validated. The process lets teams of engineers in several countries work on a part simultaneously while getting input from marketing, logistics and intellectual property executives.

“The days of engineers working alone at drafting boards and then passing on their

work to the next person are long gone,” explains Kevin Fowler, Boeing’s vice president of systems integration for the 787. “We now sit in teams around virtual, digital drafting boards. This is just the reality of our business.”

Other industries have used cradle-to-grave 3D software before, but Boeing took things to a new level, given the complexities of its products. “Boeing has pushed this the furthest,” says Xavier Fouger, director of Dassault’s PLM Academy. As engineers shifted some parts from aluminum to composites or titanium, for instance, they were able to determine if the new designs would work and what effect they would have on other components, well before the start of production. The rapidly improving software has enabled engineers and designers to accomplish things that were impossible only three years ago, according to an executive familiar with the software.

Clearly, not everything has gone smoothly with the Dreamliner. The twin-engine, wide-bodied, 200- to 300-passenger jet, featuring increased use of composite materials and designed for optimal fuel efficiency, has been plagued by production delays.

But the project also exposed a separate problem for Boeing, one with long-term implications for the future of computer-aided design (CAD): Working with the fast-developing software was totally alien to some Boeing engineers. The burden of training them “wasn’t inconsequential,” Fowler says.

So, to address the future need for software-savvy engineers, the company has now joined with Dassault and the Georgia Institute of Technology in a new educational effort—called K2E—to bring PLM engineering concepts and software to students of all ages. Now underway at Georgia Tech’s School of Aerospace Engineering, the K2E project aims to help schools produce global engineers who are both conversant with 3D technologies and comfortable working in real time with geographically far-flung teams of coworkers.

The scope of this program is what distinguishes it from others, according to Fouger. In the past, education initiatives focused on only one segment of the education supply chain at a time: K-12 or higher education or professionals. K2E, which stands for kindergarten-to-employment, targets the entire continuum of students and seeks to introduce curriculum changes at all levels simultaneously. “We realized the need to connect them all,” says Cedric Simard, Dassault’s worldwide education marketing manager. The full-spectrum approach should interest more youngsters in engineering at an earlier stage. But it is also intended to hammer home to students at every level that their engineering education needs to be continual, in much the same way that the new software is designed to manage the total product life of an airplane.

“Continuity is one of the philosophical pillars of K2E–the need to consider education as a lifelong process,” Simard says.

The Next Generation

Boeing has always invested time, effort and money in training its engineers. But the speed at which the software changes makes it hard to keep up. The company realized it needed to start advocating changes in the engineering education curriculum, so that the engineers it hires are both skilled with 3D CAD and ready to tackle its ever-increasing sophistication.

Meanwhile, Dassault has also been taking education seriously because so many of its client companies have struggled to locate engineers capable of mastering its newest software. So when Dassault approached Boeing about financing and promoting a novel platform to introduce the concepts of PLM engineering and 3D software—not only to college students but also pupils ranging from grade-school kiddies to professionals—Boeing was highly receptive.

Though at present only Dassault, Boeing and Georgia Tech are involved in this K2E project, the plan is to move beyond aerospace to bring in companies from a variety of industries, as well as more universities, both in the U.S. and abroad. Clearly, PLM engineering will affect the design and manufacture of products in most industries, from automobiles to consumer goods to ships. And engineering schools know their curricula must keep pace with industry’s changing needs. “It is no coincidence that this is happening now,” Fouger says. “Education systems across the world are being challenged to produce more efficient engineers.”

Helping Schools Catch Up

A key goal of K2E is to close the gap between industry, which uses the latest CAD tools, and academia, which is often years behind the software curve. So the companies will provide schools with the latest software and curricular additions at nearly the same time those technologies are released to companies. High school students will work with a version of Dassault’s industrial 3D CAD software, CATIA (Computer-Aided Three-dimensional Interactive Application). Children ages 7 to 15 will use Cosmic Blobs, Dassault’s 3D animated CAD software for kids, which has already been used successfully in school programs. Earlier, together with partners IBM and Nokia, Dassault ran a project called MobiCube in which students in 20 Paris schools used Cosmic Blobs to design mobile phones.

Dassault and Boeing both have long-standing relations with Georgia Tech, which is why the school was selected to join the pilot. And like Boeing, Georgia Tech immediately cottoned to the idea. “There is a strong interest at Georgia Tech in the whole supply chain of engineers, so we saw this as an opportunity,” says Daniel P. Schrage, professor of aerospace engineering, who is helping to implement the program. “K2E is attractive because it involved the full spectrum, from students to practicing engineers.”

At the university level, the injection of 3D software revolves around three projects, each of which targets a different segment of the student body.

The first is a new approach to an intercollegiate competition called Design/Build/Fly. This year it’s incorporating 3D software for the first time, as well as graduate students who will serve as mentors to the undergraduates. The new master’s project lets students use the latest software to design a helicopter, and it has a strong international component. Students at Georgia Tech’s main Atlanta campus will work with teams based at its campuses in Savannah, Ga., and Lorraine, France, as well as with students at Konkuk University in South Korea. The third project focuses on older students—professional engineers returning for a master’s in systems engineering. They’ll work with a complete CATIA model of a Saber Jet supplied by Boeing.

While Schrage’s focus is at the university level, Anthony A. Docal, student enrichment director at Georgia Tech’s Center for Education Integrating Science, Mathematics and Computing, will work to introduce PLM design concepts and software to some 30 to 40 middle and high schools across Georgia. Building on an ongoing statewide competition in which students design and build small gliders, the plan is to develop design-based activities that eventually will filter down to the elementary feeder schools. “You’ve got to catch these students early, at least at the middle school to early high school level, so they don’t get bored with science and math,” Schrage says.

Georgia Tech’s summer programs are also aimed at various populations of teachers and high school, middle school, and elementary school students. At one level, graduate students will work with middle and high school teachers, training them in 3D design at Georgia Tech’s aerospace engineering labs. The teachers will be considered interns, and will get help in developing activities to introduce PLM software into their classrooms, as well as after-school programs.

Another element is Georgia Tech’s high school summer program in which students will use CATIA to design things they are interested in. Last summer, one student designed a piano in 3D, while another created a version of a Swiss Army knife. Yet another plan is to start an on-campus summer camp for fifth through eighth graders that uses Cosmic Blobs. Schrage likes the hands-on factor of these initiatives. “I think it is important. Kids get excited if they can design things.”

For now, Dassault won’t say which other companies and schools it expects to join K2E, though Fouger hints that an automaker may be the next to sign on. Neither is it saying publicly how much is budgeted. “Appropriate resources” will be spent to ensure success, the company says. But clearly those involved are thinking long term.

“The project will have reached its cruise speed in about 20 years,” Simard says, “when today’s 7-year-old pupil will be 27 years old and earning a Ph.D.” Or working at Boeing and helping to develop, build and maintain future aircraft that has yet to be dreamed.

Thomas K. Grose is a freelance journalist based in Great Britain.

Category: Features